In recent years, intelligent manufacturing continues to be hot, with the promotion of technology and technology and Internet giant capital, in the manufacturing industry to bring great impact. In contrast, the anxiety of traditional manufacturing enterprises is constantly amplified. The digital transformation of the manufacturing industry is imperative, so how to carry out digital transformation?

Manufacturing digitalization mainly includes process digitization, equipment digitization and management digitization. Management digitization is particularly critical, how to innovate business management mode through digital means, improve the quality of products and services, to create the ultimate customer experience, is the digital era of each enterprise needs to solve the problem.

Enterprises based on the production and operation of the data generated by the analysis, mining and use of their own business through the digital means of presentation, optimization and management, to provide guidance for the enterprise's strategic decision-making, operations management, market services and other business activities, to enhance the ability to fine-tuning of the enterprise's operations and the competitiveness of the industry, and to become a powerful engine for the enterprise to cultivate new models and new business models.

From the perspective of the whole life cycle of enterprise product production and manufacturing, the demand for BI in the manufacturing industry is mainly as follows.

1. In the product design stage, through the analysis of user data, competitor data, public opinion data, insight into user needs, product use feedback, etc., tailored to meet the needs of the user's products to meet the demand for small-scale customized production.

2. In the manufacturing stage, you need to monitor the production process data, including product quality, product cost, production time, capacity utilization and other indicators, production abnormalities in a timely manner, to ensure that the production cost, quality, delivery in a controllable range.

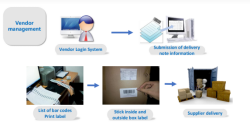

3. In the logistics and distribution stage, through data analysis, real-time monitoring of logistics and distribution, inventory, optimize the efficiency of logistics and distribution.

4. In the operation stage, through the collection of sensor data, timely detection of equipment failure and other issues, to achieve efficient product operation and maintenance.

5. In the maintenance stage, combined with equipment data to analyze the causes of equipment failure, develop a reasonable maintenance plan to extend the life cycle of the equipment.

In the face of the digital needs of manufacturing enterprises in the transition, based on the industry's thinking, as well as combining the consensus of many business managers, from the perspective of BI selection, for manufacturing enterprises to give the following suggestions:

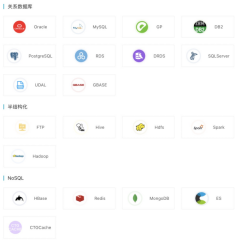

1. Data connectivity

Manufacturing enterprise data is complex and diverse, in addition to business system data, manufacturing system data, there are a large number of manual data, so the need for BI tools not only support the mainstream relational databases, MPP databases, textual data sources, but also need to support manual data filling and API interfaces, able to meet a variety of data access needs. For the manufacturing industry, the degree of enterprise digitization is different, the data from different sources, you need to support MES, MRP, ERP and other systems data fast docking, to meet the needs of enterprises to converge on multiple types of data.

2. Agile ETL capability

ETL engine is the basis for data preparation and data governance. In the process of building enterprise big data system, most of the ETL work should be placed on the dataplatform level to complete, the BI system only needs to undertake some simple ETL work, such as correlation, grouping, de-emphasis, aggregation and so on.

Therefore, the need for BI tools for business people to provide, lightweight, agile ETL capabilities to help business people on the production equipment and business process data to quickly data cleaning, transformation, correlation and aggregation.

3. Data Modeling Capability

Agile BI by incorporating the technical architecture of big data, focusing on distributed computing, memory computing, column storage, library computing and other technologies to achieve real-time analysis of data, to achieve hundreds of millions of data can be a second response, eliminating the complex modeling process, only light modeling to meet the needs of exploratory analysis, self-service analysis.

Manufacturing BI tool modeling support data source indicators visual configuration, SQL configuration, combined dataset, API dataset, ETL dataset and external import and other ways, business personnel can "0" code to complete the data modeling, and at the same time adapted to a variety of high-performance columnar databases for a large number of production equipment data, to achieve billion-data query in seconds. Realize hundreds of millions of data query in seconds.

4. Fixed report development

Fixed report development is mainly oriented to technical personnel, technical personnel are more concerned about the efficiency of report development, including the richness of the chart components, the richness of plug-ins and materials, secondary development support capabilities.

Secondly, Chinese-style complex reports to meet the situation, often corporate strategy departments, financial departments may have more Chinese-style complex report requirements, and foreign BI products in the development of complex reports performance is obviously weak.

5. Large screen design capabilities

Management cockpit is one of the main needs of the enterprise, the cool design of the big screen often becomes the "finishing touch" of the BI project, is an important factor in the success of the BI project.

6. Self-service analytical BI

In the era of big data, the business sector's demand for BI has transitioned from the traditional Kanban boards and indicators to analyzing and mining operational issues from big data. Instant, diverse data analysis needs are gradually popularized, and self-service BI for business personnel has become a trend. However, business people lack development ability, how to make business people can use, use well, use accustomed to self-service BI has become the focus of attention of enterprises.

Analysts can drag-and-drop operation for on-the-spot analysis of data correlation, drill down layer by layer through indicators to form a brain-map style analysis story, and the analysis results can be quickly presented in charts and graphs. The analyst can easily get the root cause of abnormal data.

7. Interactive Data Reporting

Collaborative BI has become the new hotspot and new trend. Collaborative BI provides real-time comments and online discussions on business dashboards. Users can send text, snapshots and pictures during the discussion process, which ultimately realizes collaborative interaction and cooperative decision-making scenarios for the team.

Multi-page PPT-style data reports to meet the data reporting business scenarios (e.g., business reporting, product quality reporting). Support page annotations, comments on analysis conclusions, and interactive comments from multiple members.